screen printing

Let's get started!

Contract screen printing and embroidery with outstanding quality, speed, and transparency.

Screen

Printing

Let's get started!

Contract screen printing and embroidery with outstanding quality, speed, and transparency.

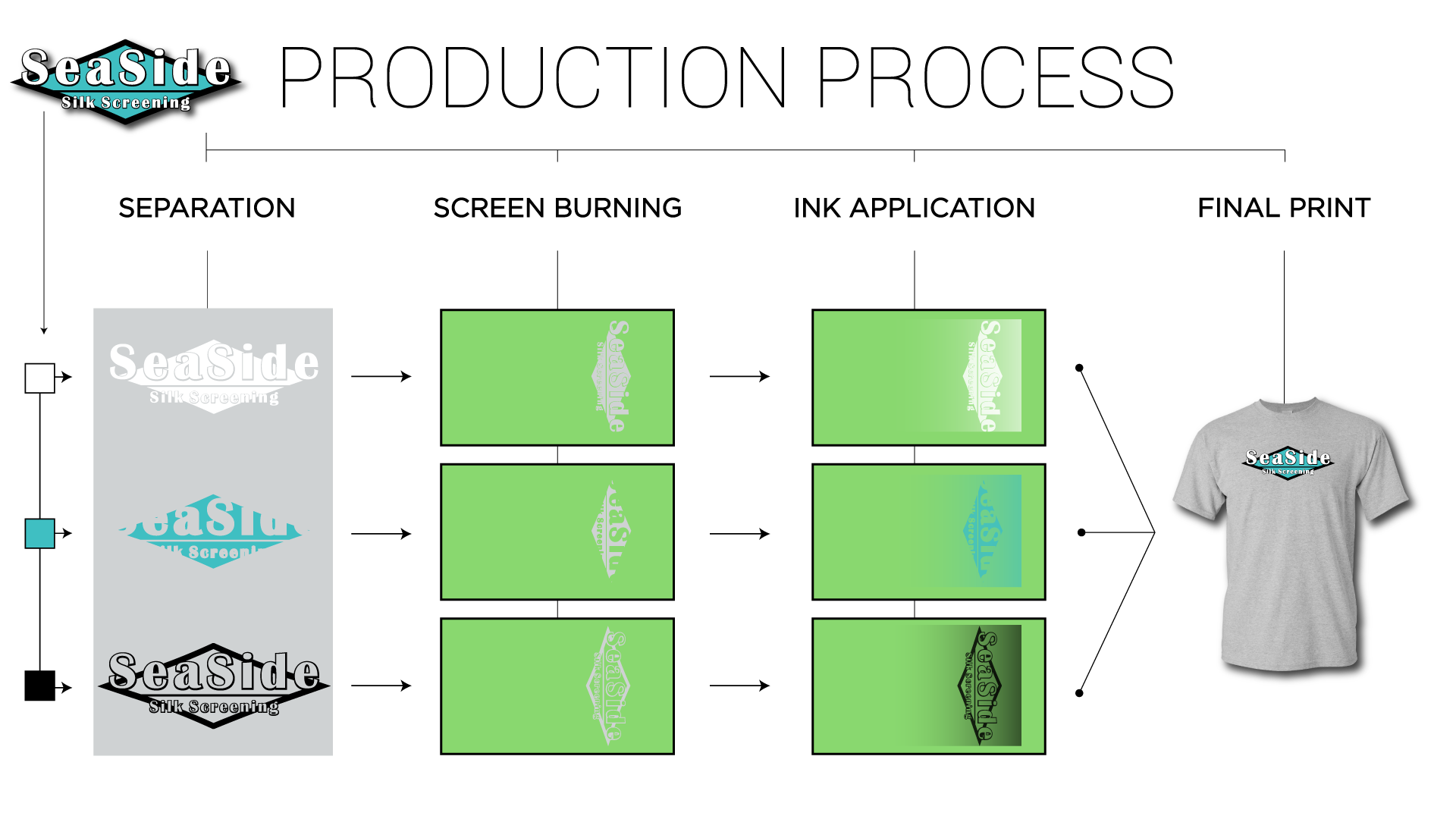

Screen Printing – The Process

To fully understand the results of decoration with screen printing, it is important that we educate you on the process of taking a digital graphic and creating apparel. While there are many variables and procedures for printing, we have listed the key specifics in a few simple steps.

Art

Our in-house apparel graphic designers will review your design and determine what method of printing would best attain the sought-after results.

Separations

Once the design is mocked up on the correct garments and approved by the client, our artists create separations – dividing the art into separate colors, creating positives that are printed on film.

Exposure

Now that we have film positives, our Screen Department creates a stencil on the individual screens using a process called exposure.

Registration

Next, our Screen Print Department will take the screens that contain stencils and align them with a precise registration process.

Screen Printing – The Process

To fully understand the results of decoration with screen printing, it is important that we educate you on the process of taking a digital graphic and creating apparel. While there are many variables and procedures for printing, we have listed the key specifics in a few simple steps.

Art

Our in-house apparel graphic designers will review your design and determine what method of printing would best attain the sought-after results.

Separations

Once the design is mocked up on the correct garments and approved by the client, our artists create separations – dividing the art into separate colors, creating positives that are printed on film.

Exposure

Now that we have film positives, our Screen Department creates a stencil on the individual screens using a process called exposure.

Registration

Next, our Screen Print Department will take the screens that contain stencils and align them with a precise registration process.

Give us a call!

Give us a call!

Spot | CMYK | Simulated Process

SeaSide can provide you with three different screen printing methods to produce your desired result.

Spot Color

Spot Color is the method of taking a vector graphic and printing it as a solid shape. This is the most commonly used process in the industry, producing clean edges and vivid colors while allowing for excellent control during production.

CMYK

The process of using specially formulated, semi-transparent inks in the colors cyan, magenta, yellow, and black to produce complex designs in the form of halftones. CMYK will produce a soft hand feel on the garment but can only be produced on white or very light-colored garments.

Simulated Process

For complex graphics that are not easily reproduced using spot color methods, Simulated Process will allow for accurate reproduction of highly detailed, digital graphics with vivid colors and a soft hand feel. Using fully opaque inks, halftones, and the talent of our graphic artists, we can produce an immense amount of detail and complexity on light and dark-colored garments.

Additional Techniques

- Underlay – A print that has a base of white, providing you with a bright, vibrant and contrasting color, even on dark garments.

- No Underlay – A print that does not have a white base, resulting in a duller print and the ink color not being a true PMS match, especially on darker garments.

- Vintage – A thin print with an aged look created by cutting back ink flow and using no underlay.

- Distressing – A print that has an aged look that is created graphically, not using print techniques.

Spot | CMYK | Simulated Process

SeaSide can provide you with three different screen printing methods to produce your desired result.

Spot Color

Spot Color is the method of taking a vector graphic and printing it as a solid shape. This is the most commonly used process in the industry, producing clean edges and vivid colors while allowing for excellent control during production.

CMYK

The process of using specially formulated, semi-transparent inks in the colors cyan, magenta, yellow, and black to produce complex designs in the form of halftones. CMYK will produce a soft hand feel on the garment but can only be produced on white or very light-colored garments.

Simulated Process

For complex graphics that are not easily reproduced using spot color methods, Simulated Process will allow for accurate reproduction of highly detailed, digital graphics with vivid colors and a soft hand feel. Using fully opaque inks, halftones, and the talent of our graphic artists, we can produce an immense amount of detail and complexity on light and dark-colored garments.

Additional Techniques

- Underlay – A print that has a base of white, providing you with a bright, vibrant and contrasting color, even on dark garments.

- No Underlay – A print that does not have a white base, resulting in a duller print and the ink color not being a true PMS match, especially on darker garments.

- Vintage – A thin print with an aged look created by cutting back ink flow and using no underlay.

- Distressing – A print that has an aged look that is created graphically, not using print techniques.

Custom PMS Matching

How we do it

Are you looking for a specific PMS match for your screen print designs? We provide this service with the use of the Pantone® approved Wilflex™ EPIC Rio ink mixing system. Using the latest pigment technology, the EPIC Rio IMS easily formulates 18 inter-mixable inks to provide you with a perfect balance of color accuracy and opacity.

What you need to know

- Every ink in the Wilflex™ EPIC Rio ink mixing system is non-phthalate and requires no bases or additives when mixing

- The CUSTOM PMS matched ink will be opaque, without compromising the color accuracy and vibrancy you desire

- There is a difference between COATED and UNCOATED Pantone® colors – when selecting a Custom PMS match, you must use the COATED Pantone® color wand to ensure accuracy

- Your PMS selection will best reproduce over white, whether a white garment or a white underlay on colored garments

Custom PMS Matching

How we do it

Are you looking for a specific PMS match for your screen print designs? We provide this service with the use of the Pantone® approved Wilflex™ EPIC Rio ink mixing system. Using the latest pigment technology, the EPIC Rio IMS easily formulates 18 inter-mixable inks to provide you with a perfect balance of color accuracy and opacity.

What you need to know

- Every ink in the Wilflex™ EPIC Rio ink mixing system is non-phthalate and requires no bases or additives when mixing

- The CUSTOM PMS matched ink will be opaque, without compromising the color accuracy and vibrancy you desire

- There is a difference between COATED and UNCOATED Pantone® colors – when selecting a Custom PMS match, you must use the COATED Pantone® color wand to ensure accuracy

- Your PMS selection will best reproduce over white, whether a white garment or a white underlay on colored garments

Social Media

Useful Links

Social Media

Useful Links