embroidery

Let's get started!

Contract screen printing and embroidery with outstanding quality, speed, and transparency.

Embroidery

Let's get started!

Contract screen printing and embroidery with outstanding quality, speed, and transparency.

Embroidery – The Process

To fully understand the results of contract embroidery, it is important that we educate you on the process of taking a digital graphic, converting it to a stitch path, and creating apparel. While there are many variables and procedures for embroidery, we have listed the key specifics in a few simple steps.

Art

Our in-house apparel graphic designers will review your design and prepare it for digitizing and embroidery.

Digitizing

Once the design is mocked up on the correct garments and approved by the client, our digitizing and productions teams create a digitized file – translating a digital graphic into stitches and stitch paths.

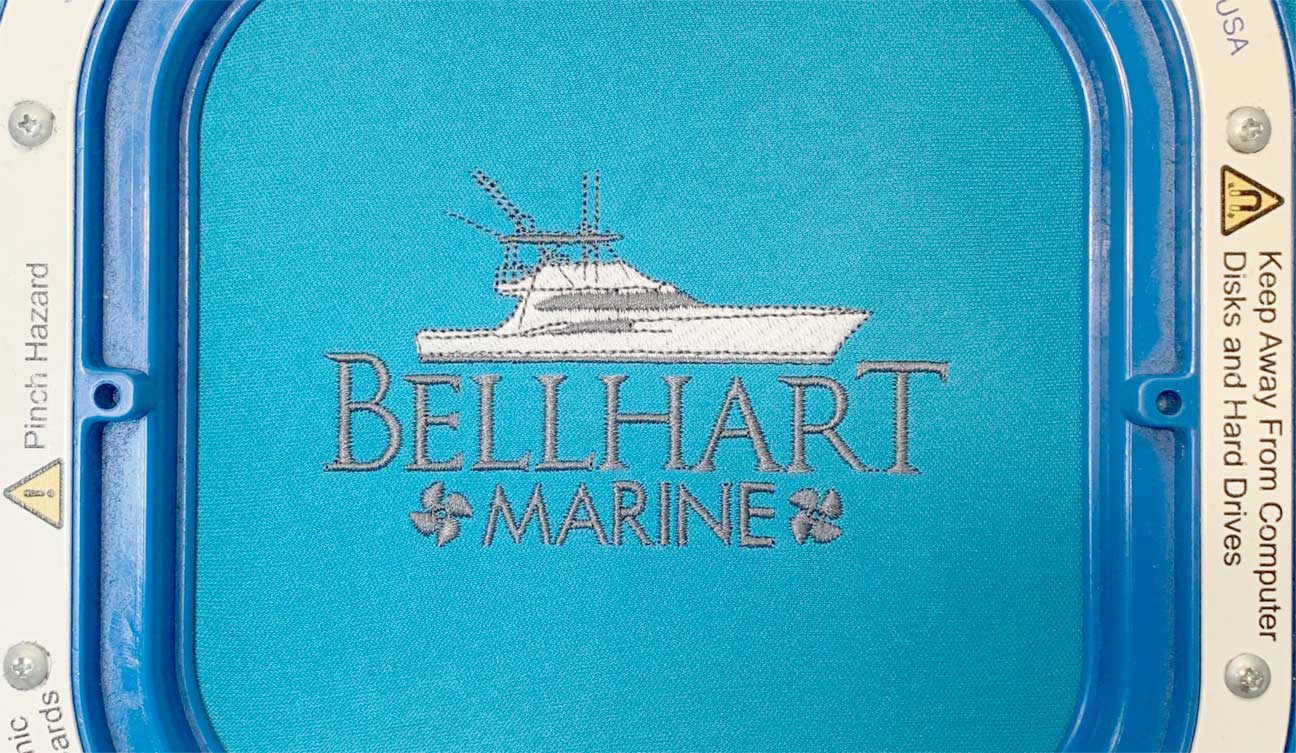

Stitch-Out

Now that we have a digitized file, our production team will do a sample stitch out, ensure the file is accurate to the proof, and send you a photo for approval.

Decoration

After you have approved the sample stitch out, we begin embroidering each garment on the order according to our production proofs and digitized file.

Embroidery – The Process

To fully understand the results of contract embroidery, it is important that we educate you on the process of taking a digital graphic, converting it to a stitch path, and creating apparel. While there are many variables and procedures for embroidery, we have listed the key specifics in a few simple steps.

Art

Our in-house apparel graphic designers will review your design and prepare it for digitizing and embroidery.

Digitizing

Once the design is mocked up on the correct garments and approved by the client, our digitizing and productions teams create a digitized file – translating a digital graphic into stitches and stitch paths.

Stitch-Out

Now that we have a digitized file, our production team will do a sample stitch out, ensure the file is accurate to the proof, and send you a photo for approval.

Decoration

After you have approved the sample stitch out, we begin embroidering each garment on the order according to our production proofs and digitized file.

Give us a call!

Backings

The use of different backings is vital to the quality of the decoration. Here at SeaSide we use a variety of Madeira® E-ZEE backing products dependent on the embroidered product.

Cut Just Right

Made for medium density designs and unstable or stretchy fabrics, Cut Just Right is to be cut away from the backside of the design.

Tear Away

Used on stable fabrics, Tear Away is removed from the backside of the design to avoid any skin irritation.

Cut Performance

Cutaway that has low visibility for lightweight fabrics and prevents the “badge effect.” Cut Performance is ideal for designs less than 8,000 stitches, high-performance wear, loosely woven fabrics, and knits.

Cap Tear Away

Specifically made for caps, it is removed from the backside of the design and results in clean, clear, and crisp designs.

Flame Resistant Weblon

A soft, flame-resistant tear away with a melting point of 450° – 460°F. Use with Madeira® Fire Fighter thread and Fire Fighter bobbins for the best results.

Waffle Tear Away

An ultra-soft tear away that is meant for lightweight fabrics and delicate designs.

Stick-On Tear Away

Tear away with release paper and pressure-sensitive adhesive that is used for hard to hoop and small products. Stick on tear away will prevent hoop burn on fabrics and is great for stretchy material.

Cut Hefty

Backing that helps provide clarity in designs, maintains it’s shaping when washed, and is cut away from the backside of the design. Use on unstable and knit fabrics.

Polymesh

Prevents show through on light-colored fabrics and is recommended for designs with narrow lines and points.

Weblon

Cutaway with a heat-activated adhesive on one side to provide a soft and smooth feel again skin.

Backings

The use of different backings is vital to the quality of the decoration. Here at SeaSide we use a variety of Madeira® E-ZEE backing products dependent on the embroidered product.

Cut Just Right

Made for medium density designs and unstable or stretchy fabrics, Cut Just Right is to be cut away from the backside of the design.

Tear Away

Used on stable fabrics, Tear Away is removed from the backside of the design to avoid any skin irritation.

Cut Performance

Cutaway that has low visibility for lightweight fabrics and prevents the “badge effect.” Cut Performance is ideal for designs less than 8,000 stitches, high-performance wear, loosely woven fabrics, and knits.

Cap Tear Away

Specifically made for caps, it is removed from the backside of the design and results in clean, clear, and crisp designs.

Flame Resistant Weblon

A soft, flame-resistant tear away with a melting point of 450° – 460°F. Use with Madeira® Fire Fighter thread and Fire Fighter bobbins for the best results.

Waffle Tear Away

An ultra-soft tear away that is meant for lightweight fabrics and delicate designs.

Stick-on tear away

Tear away with release paper and pressure-sensitive adhesive that is used for hard to hoop and small products. Stick on tear away will prevent hoop burn on fabrics and is great for stretchy material.

Cut Hefty

Backing that helps provide clarity in designs, maintains it’s shaping when washed, and is cut away from the backside of the design. Use on unstable and knit fabrics.

Polymesh

Prevents show through on light-colored fabrics and is recommended for designs with narrow lines and points.

Weblon

Cutaway with a heat-activated adhesive on one side to provide a soft and smooth feel again skin.

Social Media

Useful Links

Social Media

Useful Links